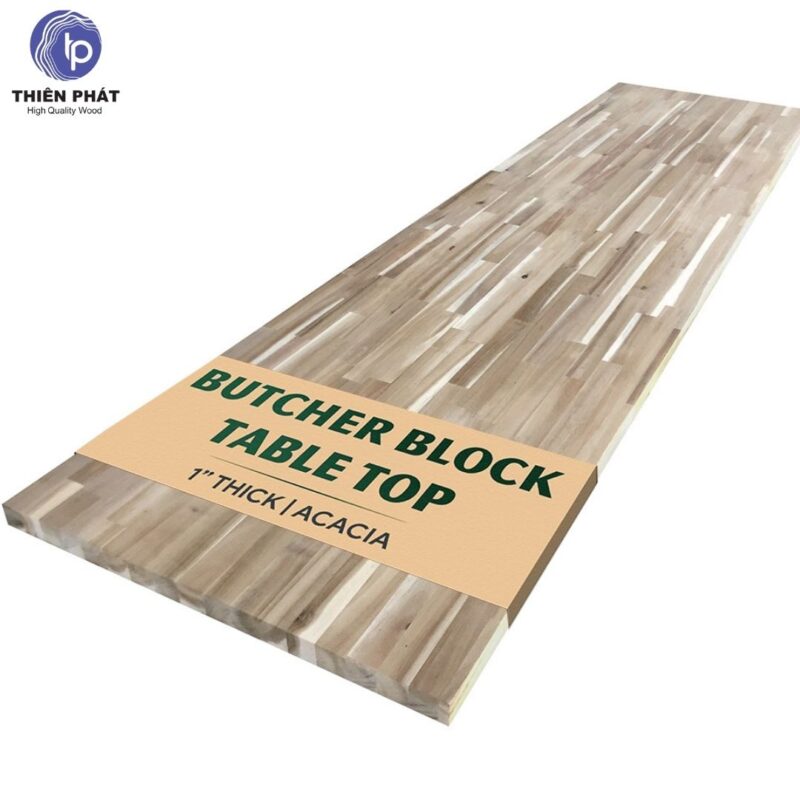

Finger-Joint Wood: Maximizing Resources & Modern Aesthetics

Finger-joint wood (also known as edge-glued or laminated lumber) is a type of engineered solid wood panel produced by joining smaller wood pieces (often reclaimed offcuts from manufacturing) together. The ends of these wood pieces are precisely cut into interlocking "finger" shapes, then permanently bonded using specialized adhesives and pressure. This process creates large, stable panels that significantly minimize warping, shrinking, and expansion.

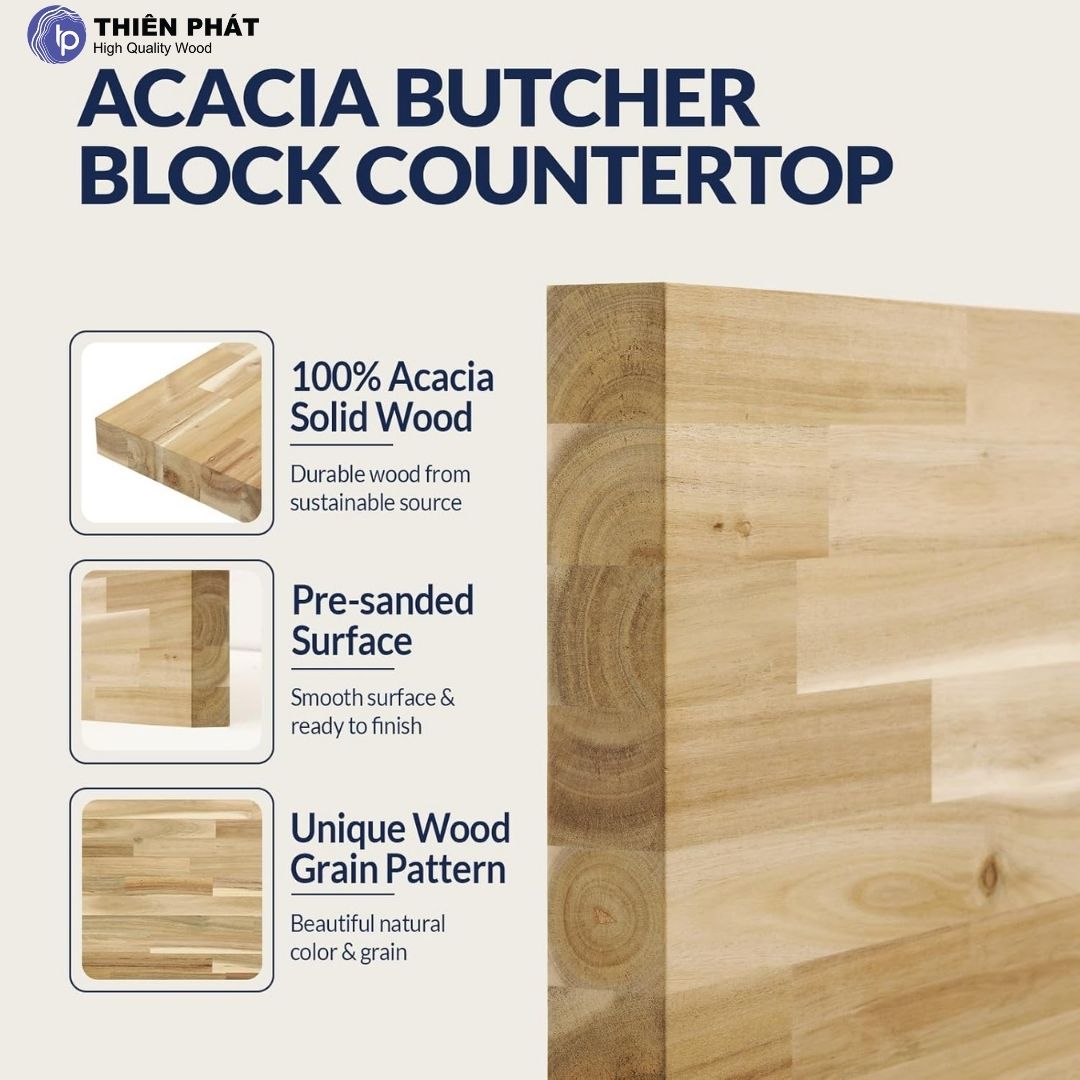

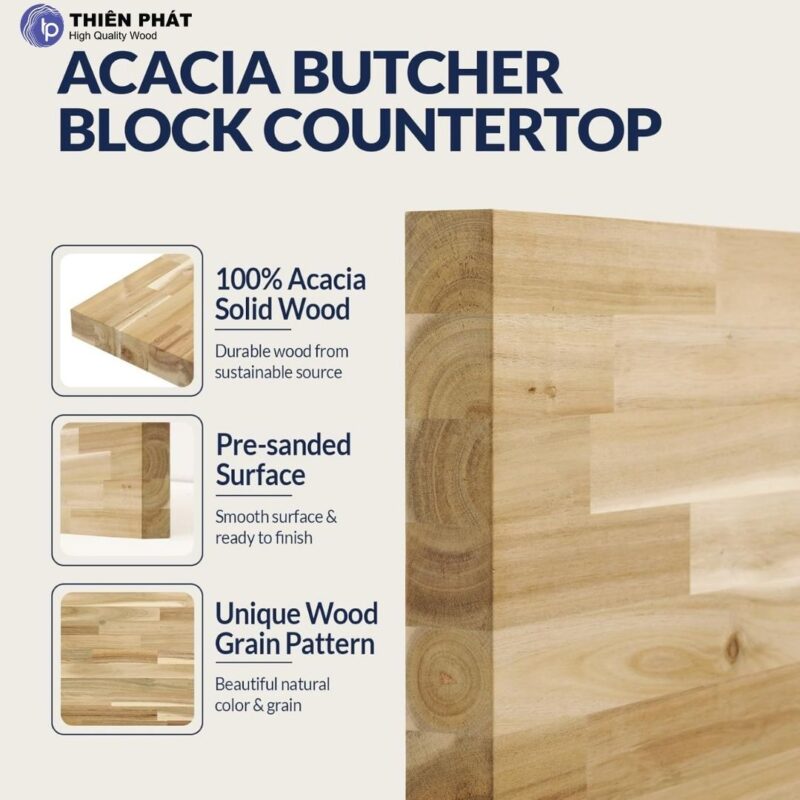

Two Popular Varieties: Acacia and Rubberwood Finger-Joint Panels

| Feature | Acacia Finger-Joint Wood | Rubberwood Finger-Joint Wood |

| Natural Color | Features a deeper, often inconsistent yellow tone, sometimes with dark streaks, offering a distinctive rustic charm. | Exhibits a bright, uniformly pale yellow, and more vibrant color. It has a smoother surface with fewer knots. |

| Hardness & Durability | Slightly softer than Rubberwood but possesses good resilience and elasticity. | Very hard, durable, and boasts excellent natural resistance to termites. |

| Aesthetics | Well-suited for products requiring robustness and a natural, rustic style. | Easy to finish, making it compatible with a wide range of styles from modern to minimalist. |

| Price | Generally competitive, often slightly more affordable than Rubberwood of comparable quality. | Commands a slightly higher price due to its attractive bright color and ease of processing. |

Diverse Color Options

A key strength of finger-joint wood is its highly customizable color versatility:

- Natural Finishes: Retains the characteristic yellow hues of Acacia or the bright tone of Rubberwood, often sealed with a clear topcoat (Polyurethane - PU) for protection and to highlight the natural grain.

- Custom Staining/Painting: The surface of finger-joint panels readily accepts stains and paints. This allows for custom coloring, from classic wood tones (like walnut or cherry) to contemporary shades (such as white, grey, or pastel blues).

- Veneer Application: A thin layer of natural wood veneer (oak, walnut, ash, etc.) can be applied to the surface, creating products with the sophisticated grain and color of premium timbers at a more accessible cost.

Thanks to the combination of these two base wood types and various surface finishing methods, finger-joint wood offers an immense range of color and aesthetic possibilities, meeting nearly all demands in modern interior design.

Related Products